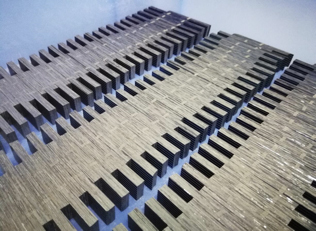

We are your true solar panel partner, much more than just a manufacturer. We keep us updated on the latest solar technology, and always choose the high efficiency solar cell to ensure high and positive power output, to delive the quality solar panel to our clients. We will check the appereance of the solar cell carefully, and cut the solar cell precisely by automatic laser cutting machine, to sort out the quality solar cell for assembly.

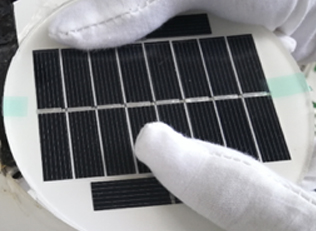

Once the solar cell is well sorted out, the next important step is to weld the solar cell. We will adopt advanced automatic machine to weld the solar cell, to maintain product consistency, increase production efficiency, and ensure high quality of our solar panel.

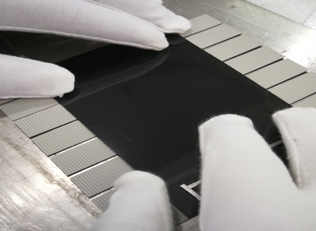

After the solar cell is string welded by the automatic machine, we will position the solar cell by a jig and make assembly carefully, and meanwhile, test the electrical performance of the semi-finished products.

After the solar cell is well assembled and tested, the next step is to laminate the solar cell - front sheet (tempered glass, or PET, or ETFE film etc) / EVA / solar cell / EVA / backsheet. Lamination will be done by a machine.

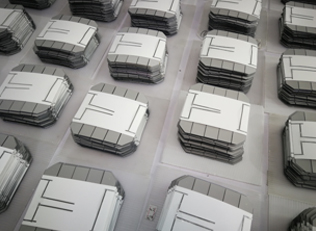

There always has some extra parts after lamination, so we need to trim all around and remove the useless extra.

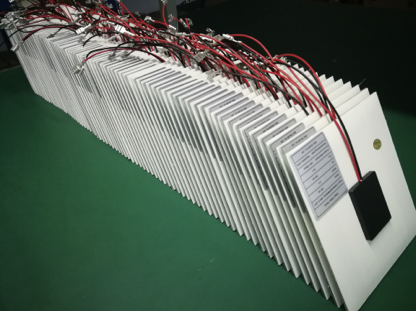

Some customers may want to solder the wire to the solar panel. And we can provide wire soldering service upon request.